Vibracoring Protocol

Vibracoring Protocol

For collecting 1-10 m cores

Background

Vibracoring is one of many subsurface sediment acquisition (sediment coring) techniques, each of which fills a role dependent on task objective and environmental parameters. Vibracoring obtains sediment samples by vibrating a core barrel into the sediment. The advantage of vibracoring is that core depths (up to 10 m) can exceed most small-boat gravity-driven type corers without adding cumbersome weight. Likewise, vibracoring is easier to accomplish and maintain than rotary-drill core methods. The vibracoring process, however, makes penetration success dependent on lithology; pure sands tend to attenuate the vibration of the barrel and slow descent, rock of course will stop descent of the barrel. The vibration will also translate to the core sample itself, and may compact the sediments or disrupt laminations or bedding in the sediment. Other coring techniques should be considered if these factors become an issue.

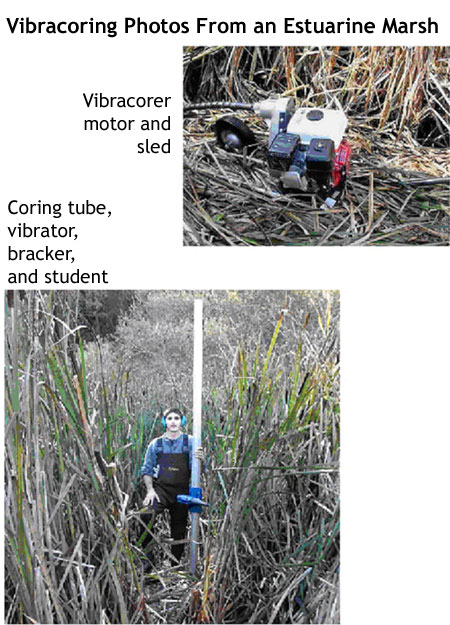

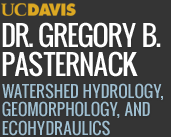

The vibrator, a STOW Model G550H, is powered by a Honda 5.5 horsepower gas motor. This unit spins a flexible cable at high speed that causes the unevenly weighted head to vibrate. The head is mounted by U-bolts to a weighted adapter that clamps to 3-inch aluminum core barrels. The setup is capable of handling barrels of any length since the adapter can easily be repositioned up the shaft as the core is driven in. Thirty-foot barrels have been the standard maximum length for this operation.

Purpose

To collect a sediment core for detailed stratigraphic and paleoecological analyses.

Materials

STOW Model G550H (engine mounted onto wheelbarrow, vibrating hose, vibrator head), regular unleaded gasoline, head-to-tube bracket, "rabbit ears", 5/16 hex wrench, adjustable wrench, old-style "bumper" car jack, aluminum core tubes, core end caps, duct tape, saran wrap, hacksaw, scissors, knife, sharpie, gloves for all workers, first aid kit

Piston: 3" dia. rubber stopper cut to fit tube and with a drill hole in the middle, 3" long eye-bolt, nut, washer, duct tape, 50' rope.

Procedure

ON THE DAY BEFORE THE TRIP

Pull start STOW motor and run for 5 full minutes; no less.

Purchase 3" dia. Aluminum irrigation pipes in 30' or 15' lengths.

Drill holes in ends of pipes to fit coring head and core catcher

DAY OF TRIP

A. Prepare Site

- Clear area around coring spot but don't disturb coring spot.

- Cut out roots using scissors

- Place motor on flat, stable surface. Motor won't start at an angle.

- Make sure the vibrator head is firmly screwed onto the vibrating hose.

- Plug the vibrating hose into the Honda motor- make sure the hose clicks into place.

- Bolt the core tube into the head-to-tube bracket at chest level, bolt the rabbit ears to the core tube above that, and then double check all bolts for tightness.

- Stand up core and hold into position over desired location

- Turn motor to "on" position, push fuel line lever to right (lower lever with fuel symbol), and pull start cord until it starts up.

- Push choke lever to right (top lever)

- At this point the motor is on but the vibrator is not going. To initiate vibration, gently push throttle lever (long silver lever). ONLY USE AS MUCH THROTTLE AS NEEDED TO PUSH CORE TUBE DOWN. Be careful!

- Push rabbit ears to make core go down. When able, stand on rabbit ears to give extra weight for pushing. Jump, push, struggle as needed!

- Once vibrator head is close to ground, downthrottle motor (but don't turn it off!), raise the head and rabbit ears, and start coring again. Repeat until core tube is all but 6" down.

- Turn off motor, close choke and fuel line, unbolt the core tube from the vibrator.

- If necessary, cut off excess tube length with a hacksaw.

- Fill barrel that is not full of sediment with saran wrap or water, depending on sediment type. This will create a suction when the core is pulled out that will keep the column of sediment in the core tube.

- Cap the tube and seal cap with ducttape. Seal must be air tight!

- Use the jack to extract the tube from the ground.